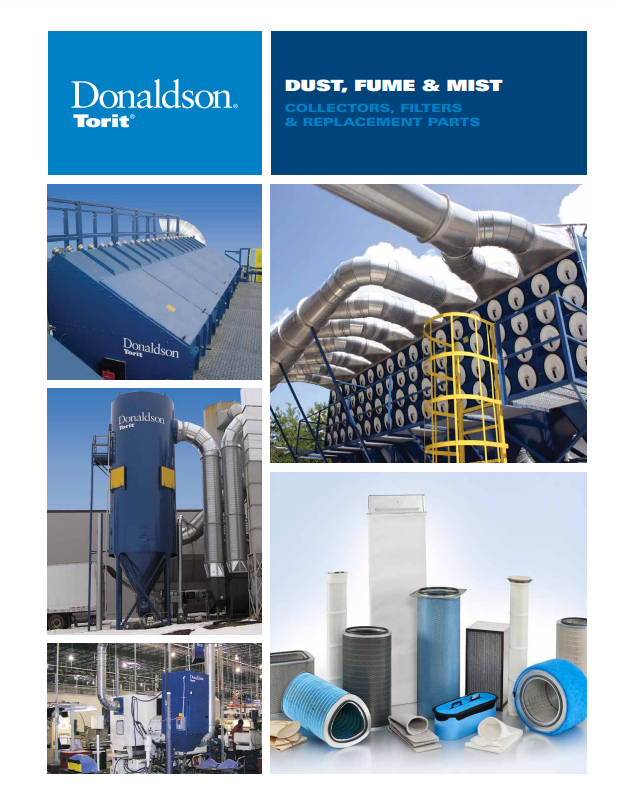

Donaldson Torit Dust Collectors

Since 1980

Free Quotes

Superior Customer Service

Since 1980

Free Quotes

Superior Customer Service

Trustworthy Dust Collectors

Dust collectors are an integral part of many plants' combustible dust compliance strategies. As such, dust collection companies have had to remain active in supplying dust collectors to support a customer’s combustible dust control strategy, by interfacing with the customer and its experts on fire and explosion protection equipment and strategies.

Identifying the Problem

Some of the common problems OSHA (U.S. Occupational Safety and Health Administration) sees include:

- Missing or ineffective dust control leading to housekeeping issues

- Dust collectors indoors, rather than outside as OSHA expects to see if the collectors filter combustible dust

- No isolation on inlets and /or outlets to prevent the propagation of any deflagration to other process equipment

- Explosion vents

- Dust collectors with no vents that are filtering combustible dust

- Dust collectors with vents that are venting to an unsafe area

Safe Dust Services

Why B/P Associates dust collectors should be part of your strategy?

Many process requirements make elimination of combustible dust, mist, or fumes impractical. However, it may still be very possible to manage the dispersion of dust within your plant by using an appropriate and effective industrial ventilation system including dust collection. A well-designed, maintained, and operated industrial ventilation system including good hoods, proper duct sizes, and properly selected collection equipment can provide effective dust control and can therefore help manage the presence of dispersed dust. This not only reduces housekeeping frequency and expenses, but also may help you reduce the risk of dust explosions in your facility, particularly the destructive secondary explosions, by helping reduce the presence of dispersed fuel in your facility.

Why B/P Associates dust collectors should be part of your strategy?

Many process requirements make elimination of combustible dust, mist, or fumes impractical. However, it may still be very possible to manage the dispersion of dust within your plant by using an appropriate and effective industrial ventilation system including dust collection. A well-designed, maintained, and operated industrial ventilation system including good hoods, proper duct sizes, and properly selected collection equipment can provide effective dust control and can therefore help manage the presence of dispersed dust. This not only reduces housekeeping frequency and expenses, but also may help you reduce the risk of dust explosions in your facility, particularly the destructive secondary explosions, by helping reduce the presence of dispersed fuel in your facility.

Share On: